With press capacities up to 250 tons, and die bed sizes up to 48×96 inches (122×244 cm), Peterson specializes in progressive die operations and, when necessary, boasts the ability to perform secondary operations.

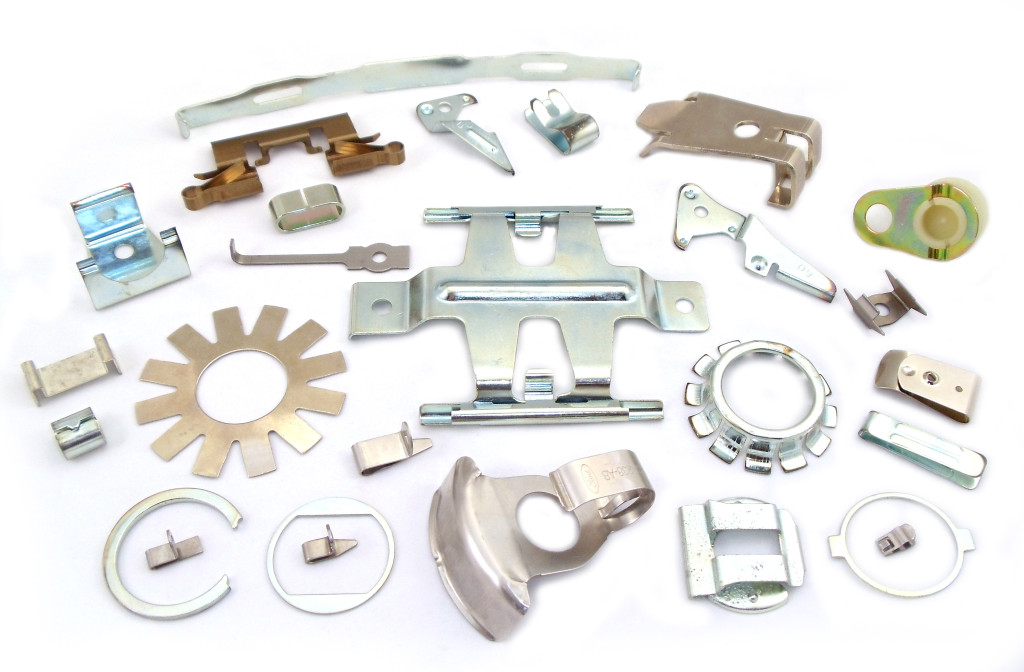

All of our state of the art plants use advanced manufacturing capabilities and craftsmanship to specialize in high carbon clips and brackets. With the capability to perform prototype, short run, and any other stamping operations on hot and cold finished steel, aluminum, stainless steel and various other metal types.

Peterson Spring is a proud supplier to a customer base consisting of OEM, automotive suppliers, agriculture, appliance and numerous other industries. Peterson Spring divisions can accommodate every application from the close tolerance and exacting industry demands of industrial, agricultural, appliance, automotive, military, aerospace, medical, dental, and telecommunications to nearly any other application imaginable. Our expertise provides us the ability to produce these and lower-tech stamping solutions through a cost-effective process permitting Peterson Spring divisions to remain an industry leader in a highly competitive manufacturing environment.

Working alongside our customers, Peterson Spring produces stampings designed to meet the unique demands of specific applications.

Four Slide (Flat or Wire)

Peterson Spring, a well-established leader in the bending of wire and strip material, continuously invests in computerized coiling and metal forming technologies enabling all of our divisions to produce complicated clips, clamps, and hose clamps in both wire and flat forms through a single operation.

Made to customer specifications for securing and fastening tubes, wires or hoses, four slide metal spring clips and metal spring clamps are manufactured by our highly specialized equipment and workforce. These products are used across a wide variety of industries in applications such as “R” clips, springs clips, fuel line clamps, hose clamps, cable control clamps and strapping restrainers.